Welcome...

Pharmaceutical Manufacturing Systems

Pharmaceutical Manufacturing

IPEC provided over 130 process and utility systems to support a customer’s largest-ever facility expansion for plasma-based fractionation and treatment manufacturing.

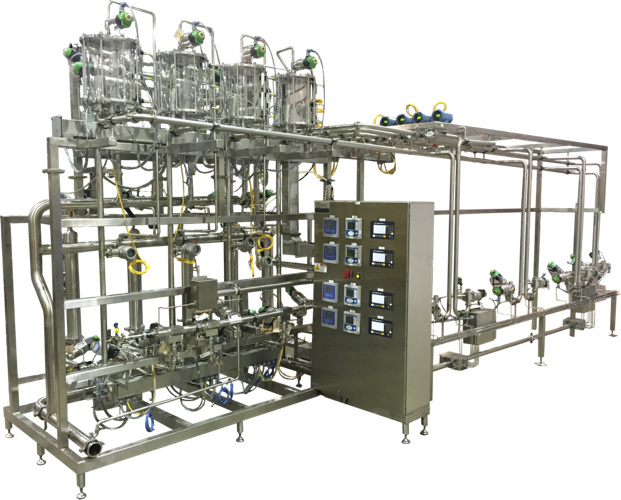

Chromatography

Two chromatography systems were supplied, each with four columns. The systems were designed for installation in a room with special access considerations for personnel and mobile equipment.

Featured Projects

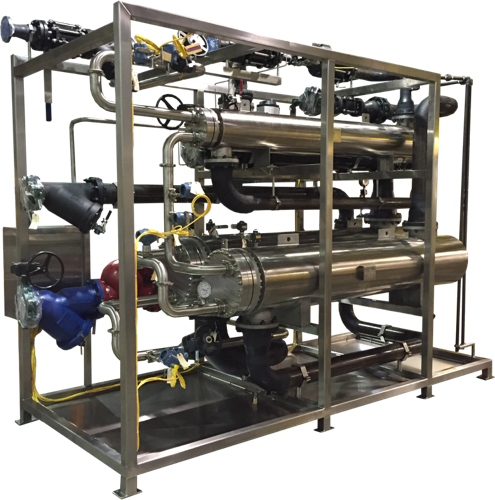

Heat Transfer

Twelve sanitary heat exchanger systems were provided to temper various process and utility solutions.

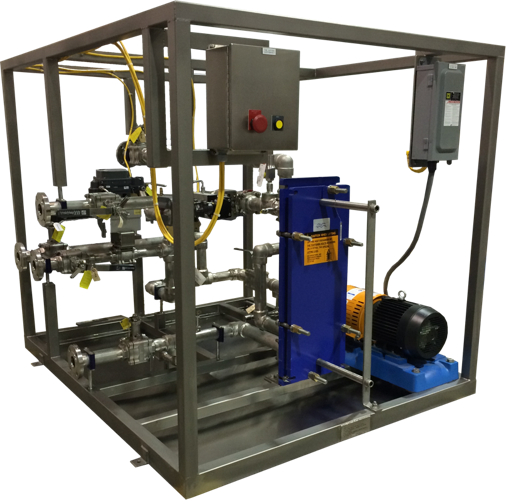

Utility Panels

Sixty Seven Utility Panels provide clean-room access to process and utility media including compressed gases, thermal media, clean steam, process solutions and purified water sampling points.

Featured Projects

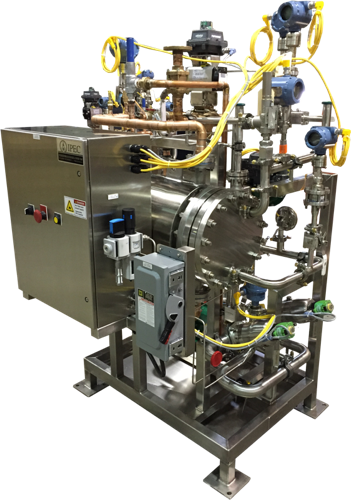

TCMs

Fifty Temperature Control Modules were provided to support dedicated tank jacket heating and cooling throughout the facility, using compact and stackable designs for efficient use of space.