Welcome...

Products

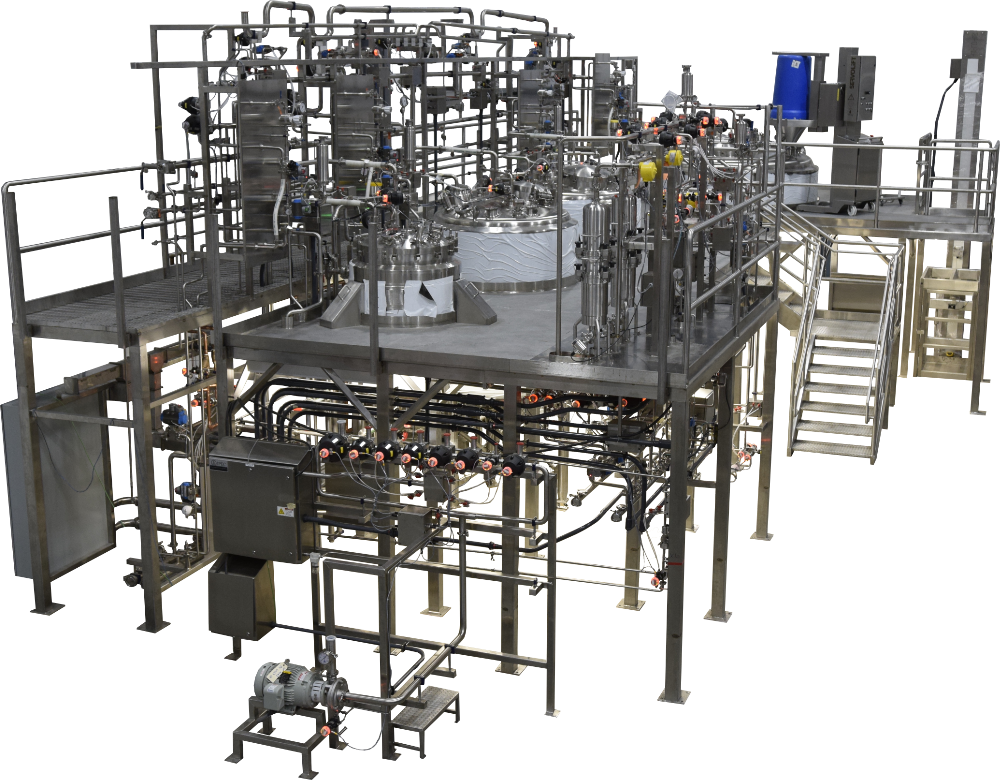

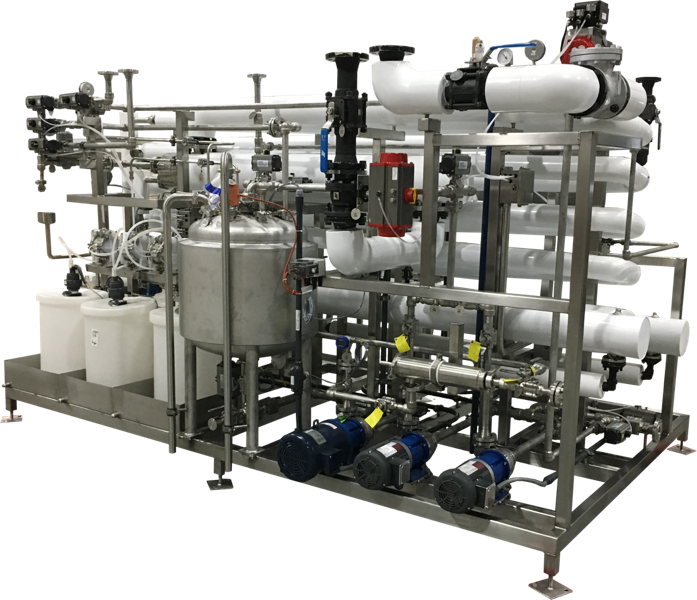

The systems shown below represent our core product lines, however our capabilities continue to grow and extend well beyond those listed.

-

-

-

-

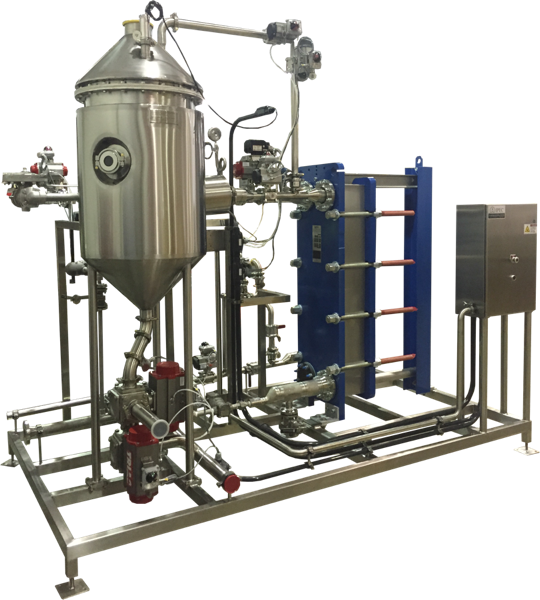

Bulk Pasteurization

pasteurizer pasteurization sterilization heat treatment batch

-

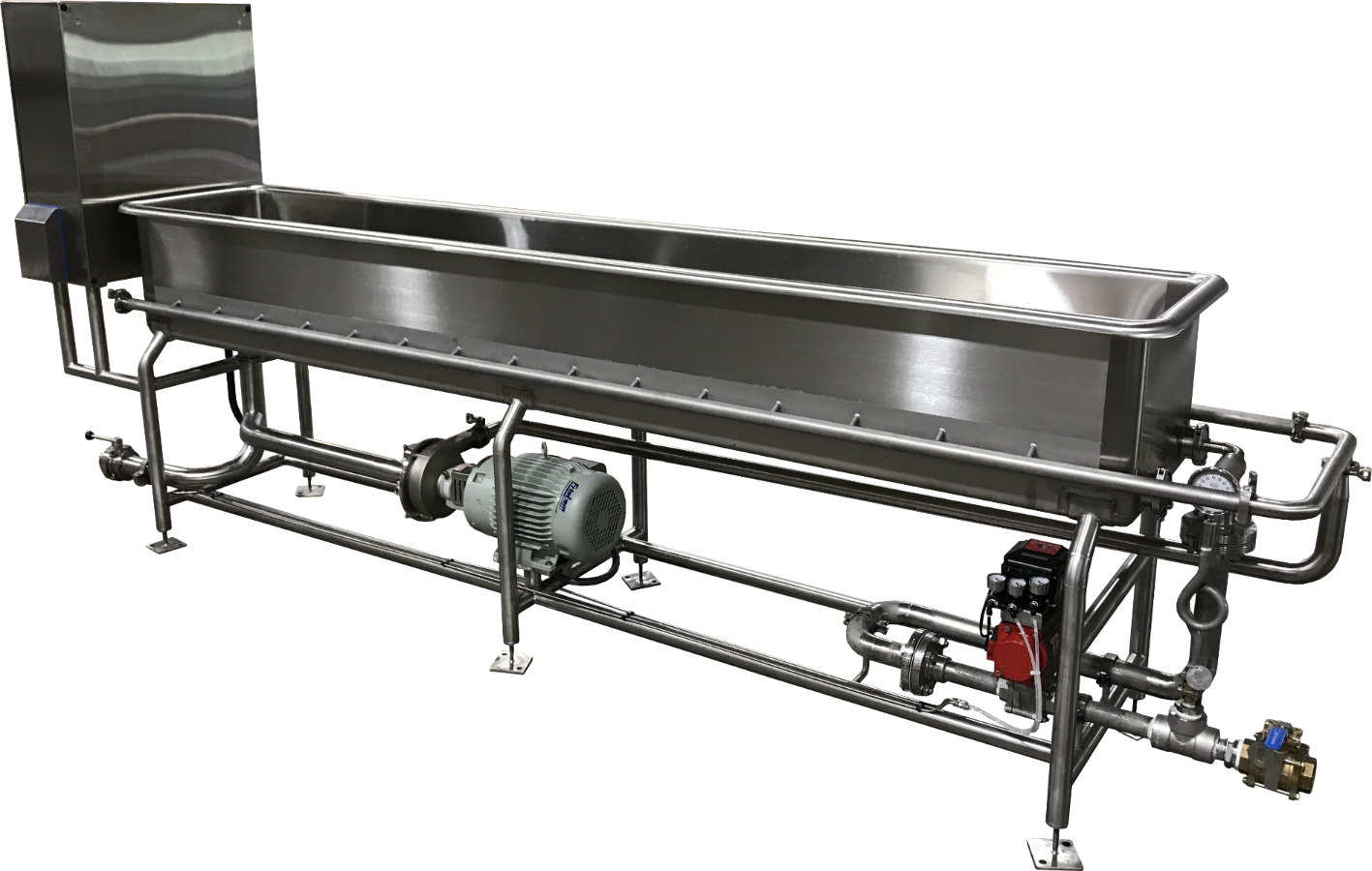

Clean-Out-Of-Place

cop cleaning acid caustic rinse wash flush heat

-

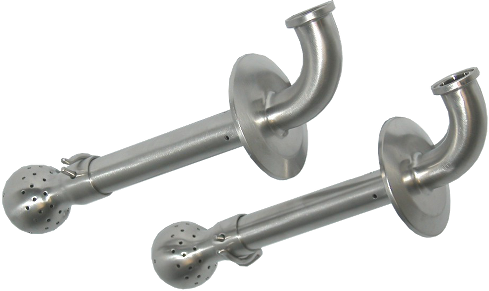

Components

sprayballs spray ball device static mixer strainer swing jumper

-

Evaporation

condense condenser concentrate evaporative purification cooking cooker flash falling film circulation plate vapor condensate

-

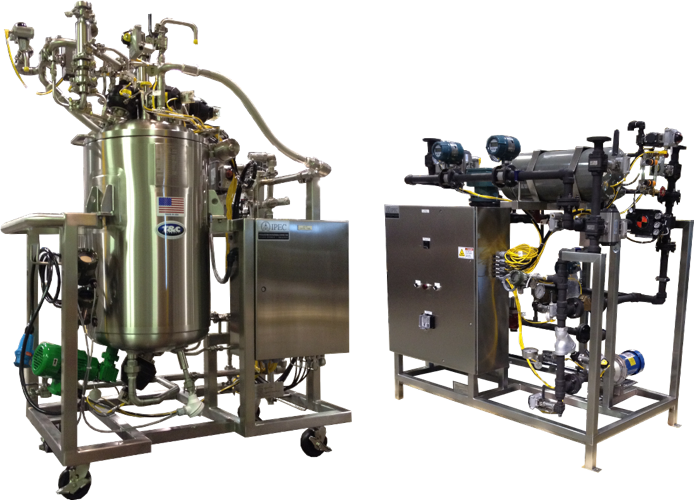

SIP Stations

steam in place sip cleaning sterilization clean

-

Tanks

tank vessel break balance atmospheric mix heat transfer jacket mix

-

Washing Systems

tote cabinet washer cleaning washing spray IBC tray hoses

UNDER CONSTRUCTION

This page is in the shop, getting welded, ground & polished.

Please check back soon.

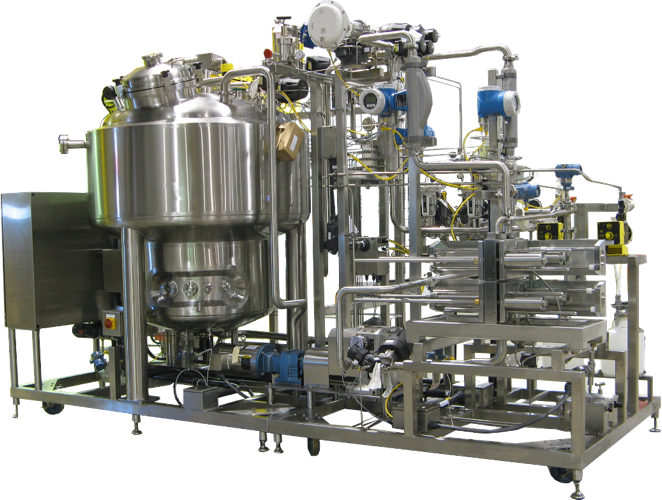

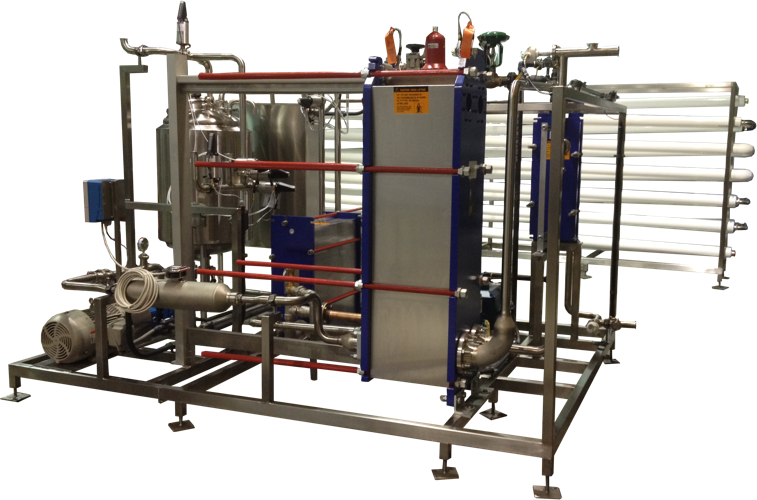

Bulk Pasteurization

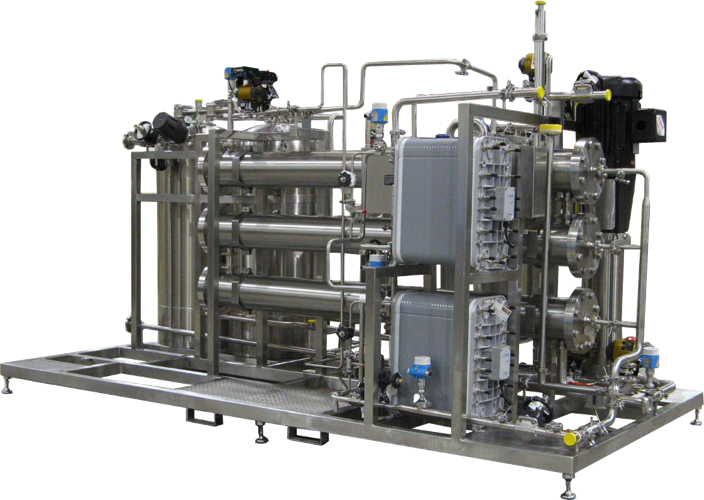

Certain pharmaceutical products respond poorly to high temperature short time (HTST) sterilization. In these cases, bulk pasteurization can be a valuable solution for inactivation of microorganisms contained within solution.

IPEC Bulk Pasteurization Systems provide accurate control of product temperature, exceptionally even heat distribution, and precise heat up/cool down rates required to sterilize even the most sensitive products. Systems can automate the complete process to include dedicated Media Prep, Heat Transfer or Final Filtration modules.

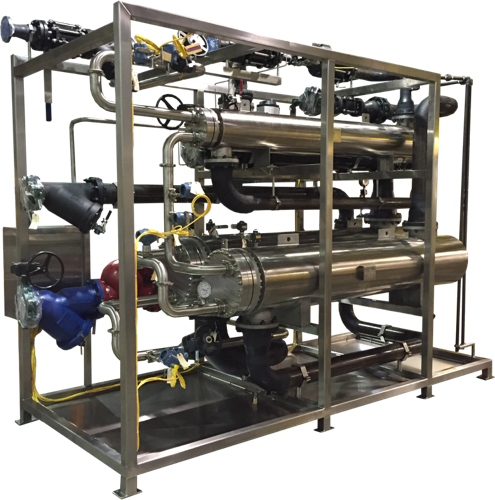

Clean-Out-Of-Place

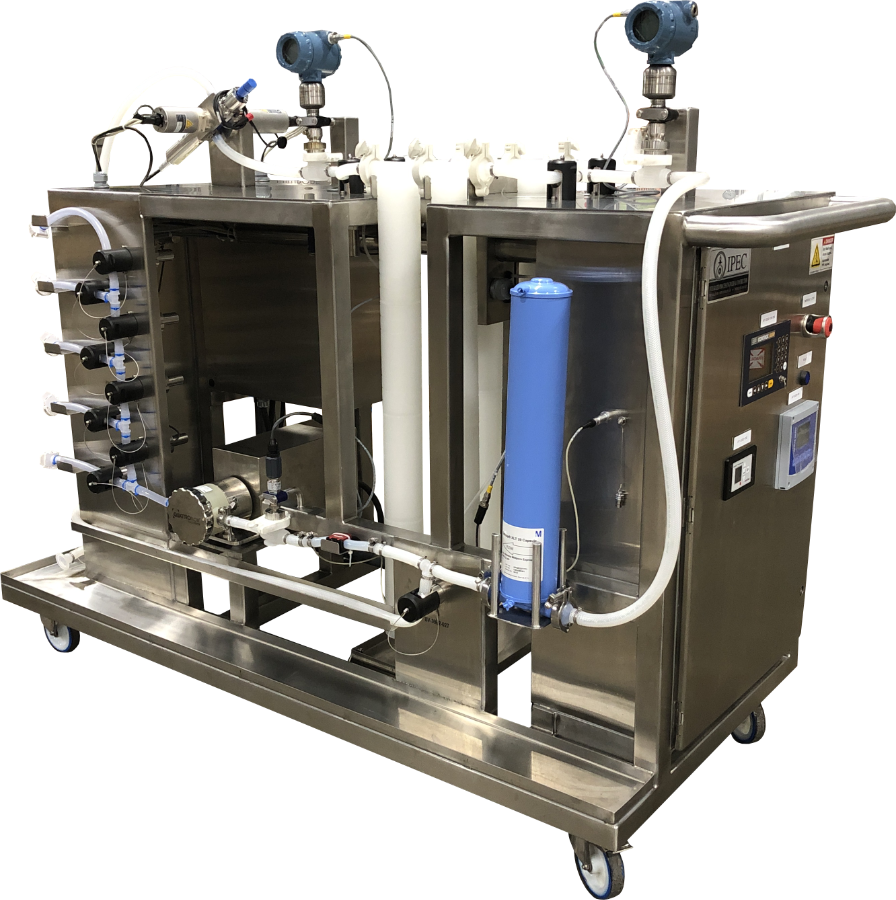

Certain components cannot be cleaned-in-place and must be removed or disassembled and cleaned-out-of-place (COP). IPEC COP Systems (Parts Washers) provide efficiency, reliability and repeatability when compared with manual washing methods.

IPEC COP Systems are custom configured based on your industry or plant-specific standards, equipment to be cleaned, and your preference for controls and automation. Systems can be made with basic functionality using manual controls, or can be highly automated.

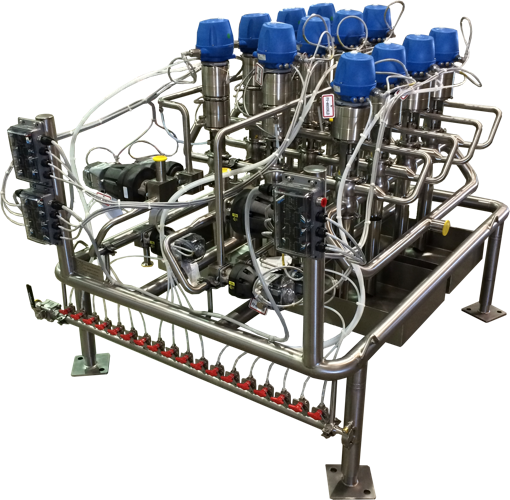

Components

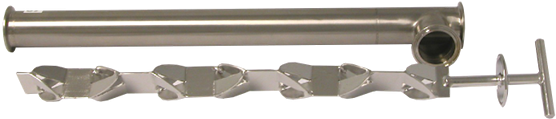

IPEC can supply a variety of custom process component as individual assemblies or as part of a larger modular sysem.

- Spray Balls

- Statix Mixers

- Strainers

- Transfer Panel Jumpers