Welcome...

Single-Use

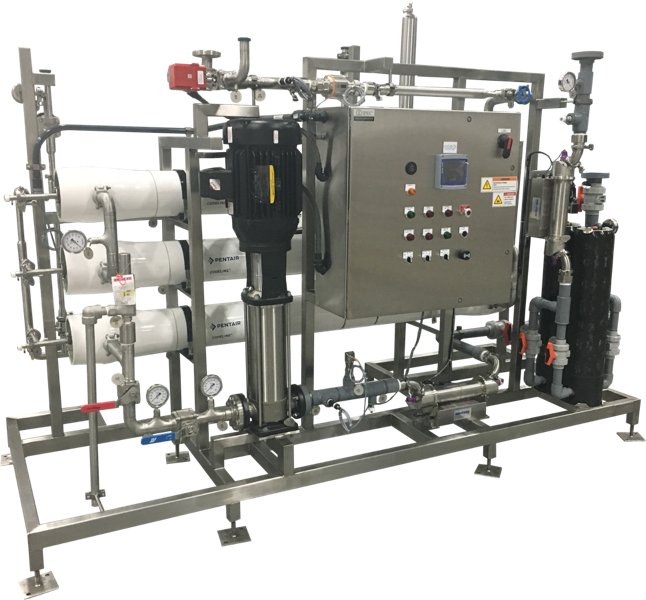

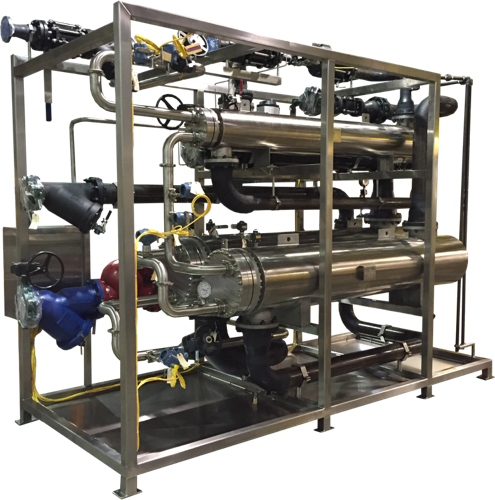

Single-Use bioprocessing has revolutionized upstream and downstream manufacturing by reducing utility costs, time to market, and contamination risk.

Single-Use

True Customization

If you find standard features and options available with other Single-Use Systems frustrating, you're not alone (IPEC can help).

Custom from Start to Finish

Most major equipment suppliers have pre-engineered offerings with rigid process designs, component manufacturers and control platforms. This frequently leaves the end-user with features they can't get, don't need, or systems that do not easily communicate with plant networks. This it not our approach.

Filtration (Viral, TFF, UF/DF, Depth)

Chromatography (Column & Membrane)

Cell Culture/Bioreactor

Gene Therapy

Vaccine Production

Mixing & Clarification

mAbs Production

Single-Use

Applications

IPEC Single-Use Systems support an increasing variety of critical biopharmaceutical pilot and production-scale applications.

Filtration (Viral, TFF, UF/DF)

Chromatography (Column & Membrane)

Cell Culture/Bioreactor

Mixing & Clarification

Gene Therapy

Vaccine Production

mAbs Production

Single-Use

Your Process

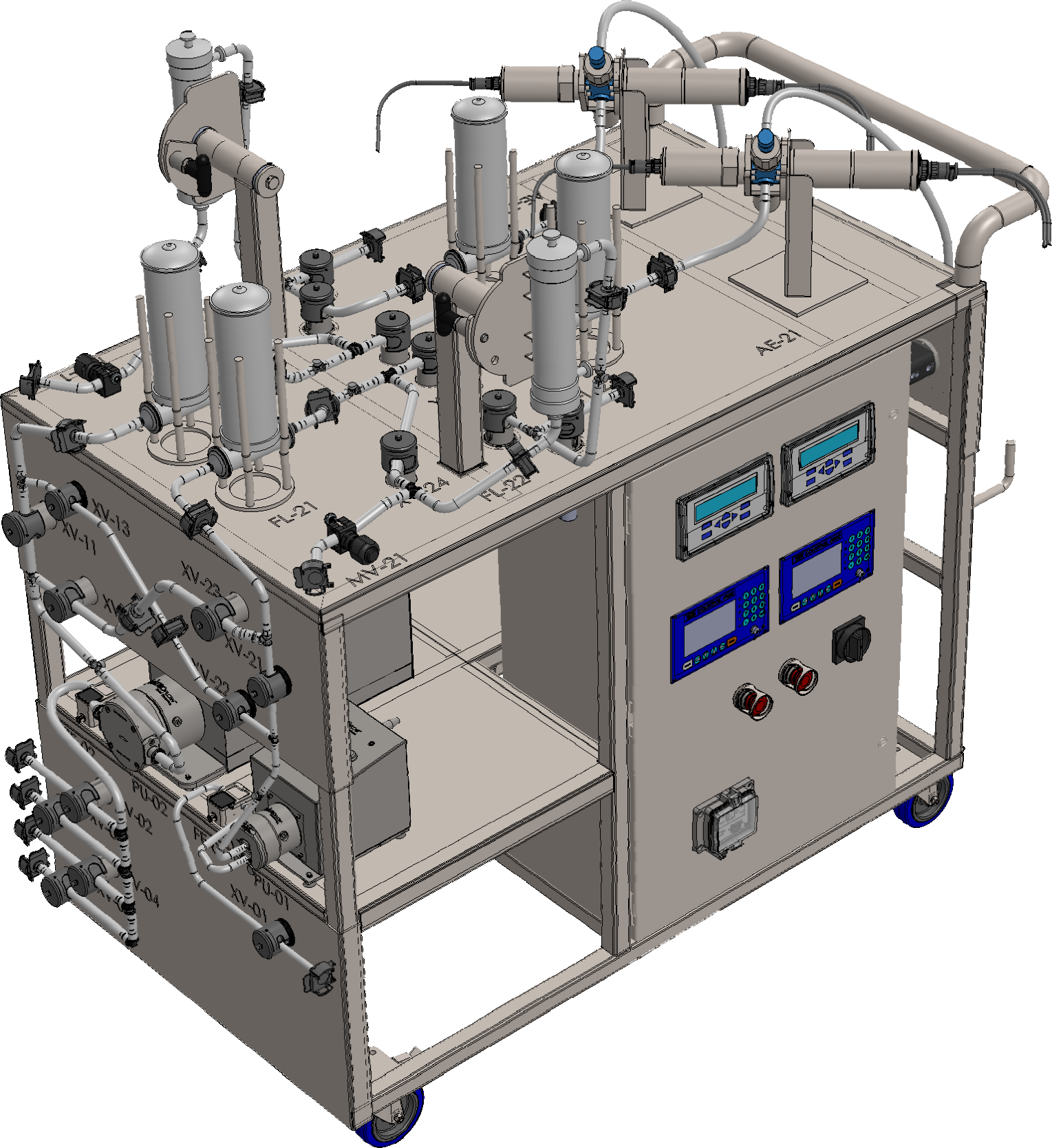

Our first step after Customer engagement is to develop a process flow diagram and evaluate preliminary flow path & system layout options.

Single-Use

Your Design

Every detail within each IPEC Single-Use System can be customized for a specific process or a highly flexible manufacturing platform.

Flexible Media

IPEC can design systems for nearly any 3rd party filtration technology (columns, cassettes, etc.). This allows the Customer to build a system around a filtration media and production rate that best suits their goals.

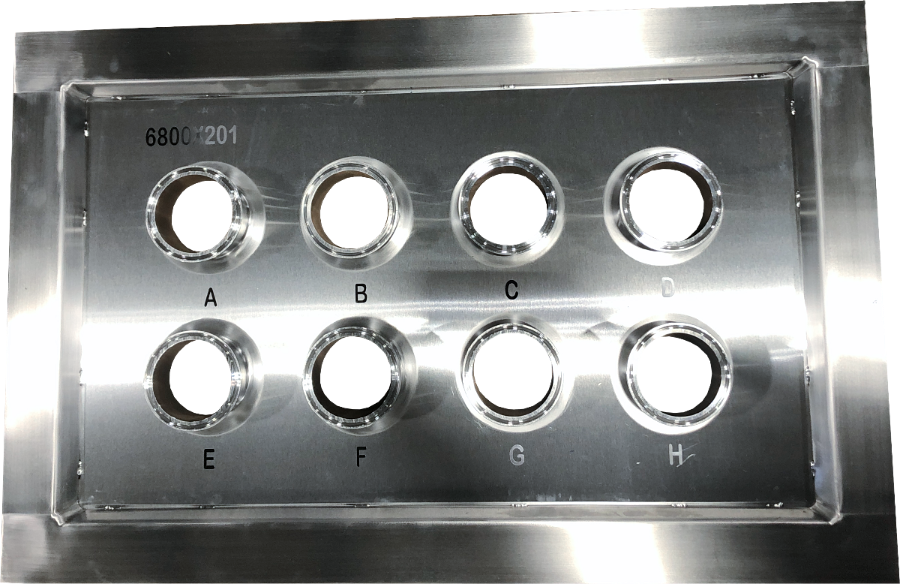

Custom Layout

Once the process is defined, IPEC designs each system with consideration for ergonomics, facility layout, minimized product holdup and any other criteria provided by the Customer.

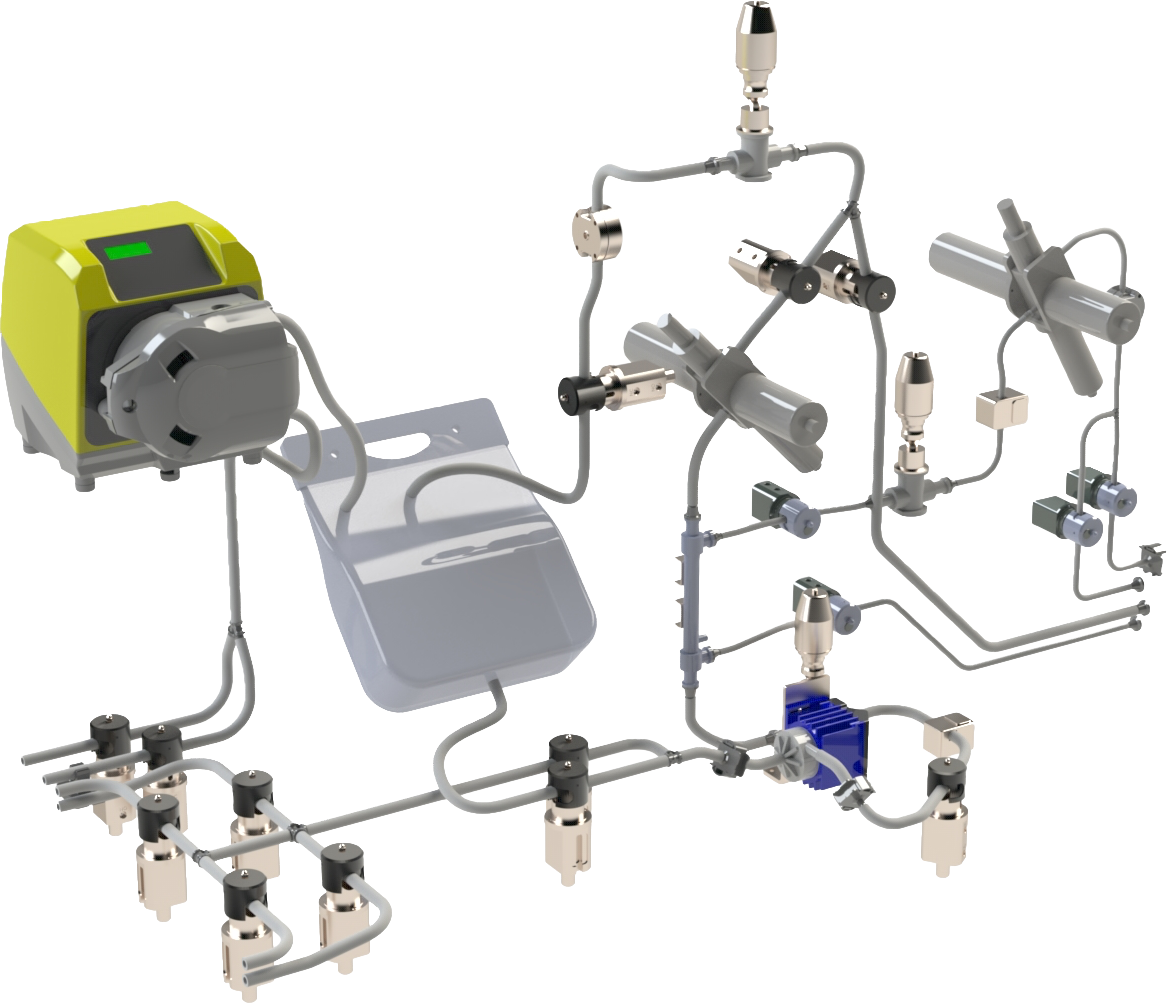

Flexible Components

The options for single-use instrumentation, valving and pumps are rapidly evolving. IPEC's experienced staff can present various options for each component with details on potential benefits during the sales and design-phases.

Flexible Consumables

IPEC can help partner the customer with 3rd-part disposable tube-kit manufacturers or work with your preferred supplier to design consumables with integrated flow tubes, bags, instruments, etc.

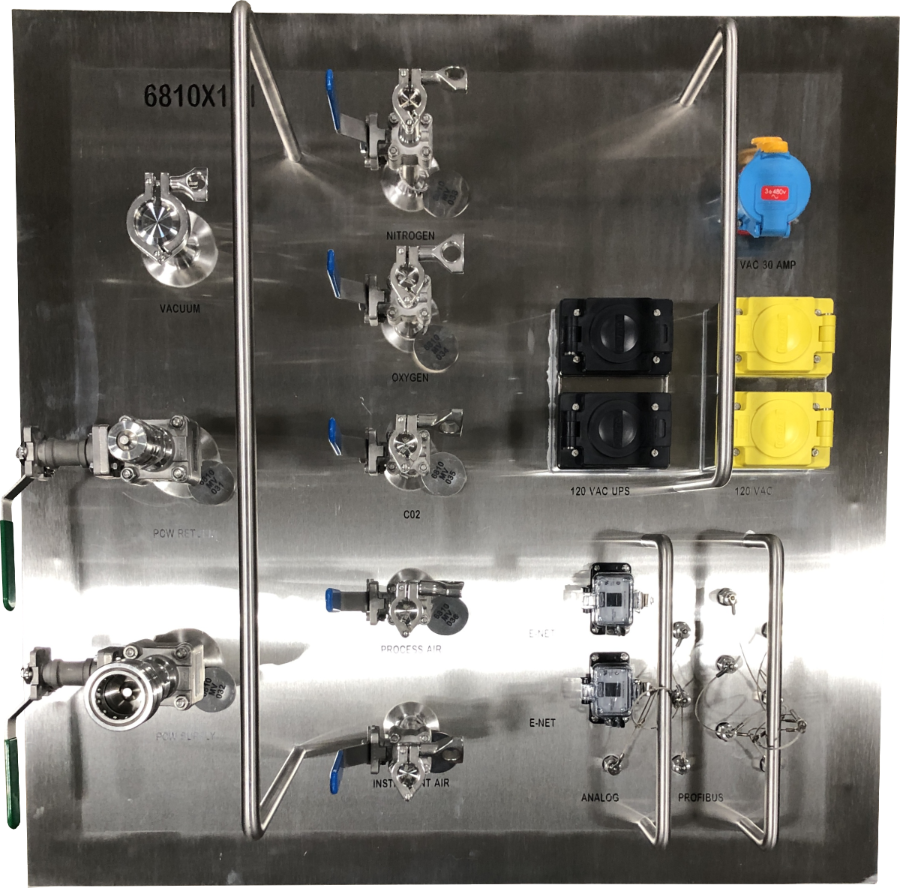

Custom Controls

Customized control platforms integrate seamlessly with supervisory plant networks or other process systems. IPEC can provide UL 508A labeled enclosures with remote I/O or local PLC systems using customer-preferred hardware.

Custom Automation

IPEC offers the most flexible options for automation in the industry. Our systems may be programmed by us, 3rd-party automation groups, or your internal staff. We also offer services to provide 21 CFR Part 11-compliant systems with optional generation of customized batch records.

Single-Use